Description

- Features

ECG series high precision centerless grinder is different from other competitors, we use spectrum analyzer to precisely analyze the machine base inner ribs and casting thickness for greater rigidity. We offer hydrodynamic alloy bearing spindle with best rotation accuracy, suitable for heavy duty jobs, and drastically increase the spindle longevity. - NC Series

With all the advantage of S series, NC series further offers lower slide (Z axis) with servo motor driven design which enables the infeed position located precisely, and the infeed distance can be controlled by numerical value.

Grinding Applications

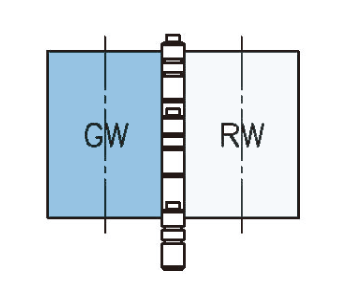

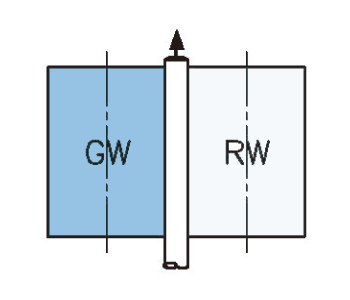

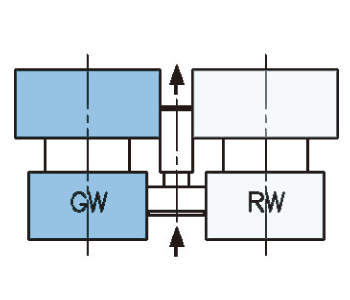

Thrufeed grinding

Thrufeed grinding

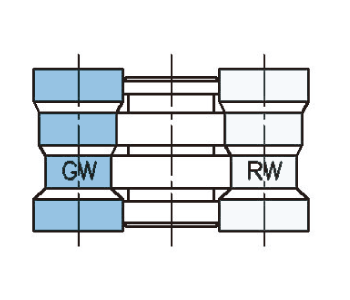

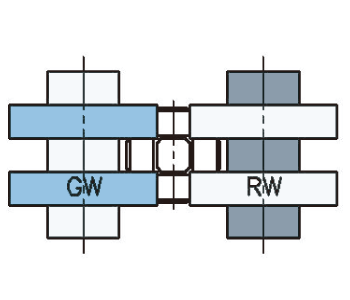

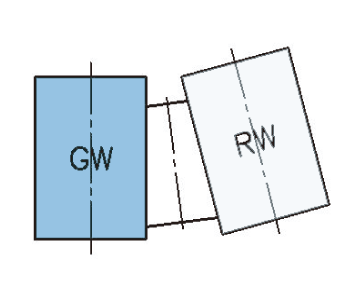

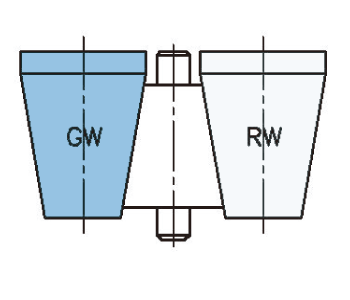

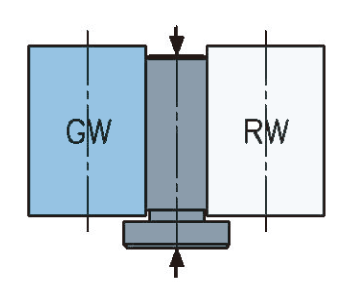

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

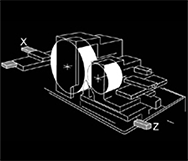

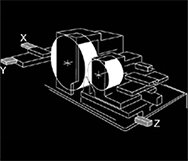

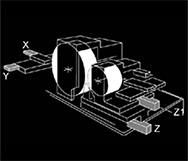

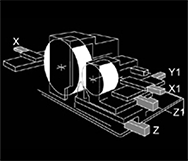

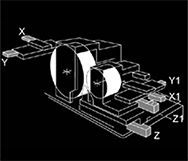

Control Axis Diagram

1 Axis

Z Axis: Upper or lower slide movement

2 Axes

X Axis: Grinding wheel dressing

Z Axis: Lower slide movement

3 Axes

X, Y Axis: Grinding wheel dressing with interpolation

Z: Lower slide movement

4 Axes

X, Y Axis: Grinding wheel dressing (Profile dressing)

Z Axis: Lower slide movement

Z1 Axis: Upper slide movement

5 Axes

X1, Y1 Axis: Regulating wheel with interpolation

X Axis: Grinding wheel dressing

Z Axis: Lower slide movement

Z1 Axis: Upper slide movement

6 Axes

X, Y Axis: Grinding wheel dressing with interpolation

X1, Y1 Axis: Regulating wheel dressing with interpolation

Z Axis: Lower slide movement

Z1 Axis: Upper slide movement

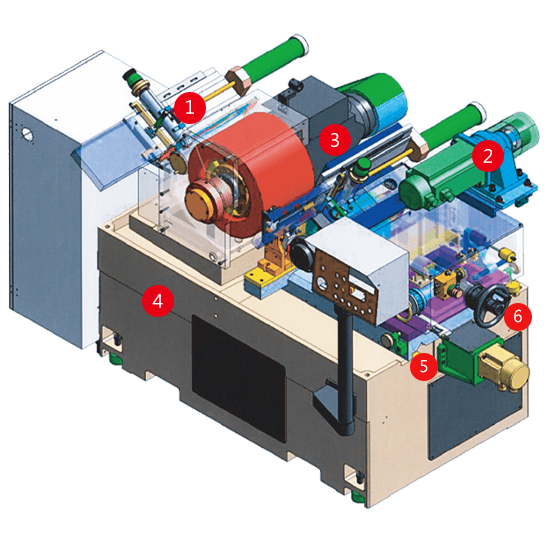

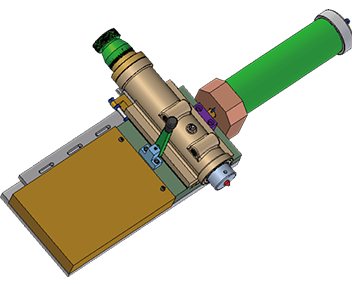

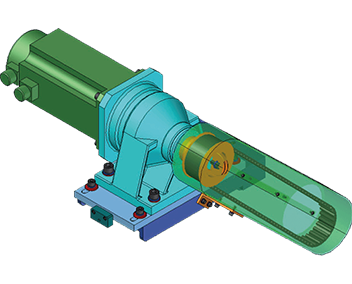

Machine Design Feature

1

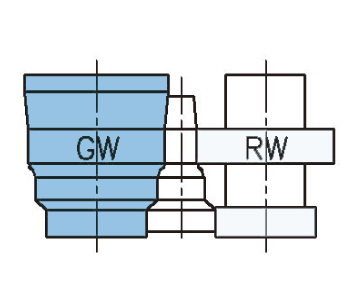

A hydraulic dressing unit on both the grinding and regulating wheels with precisely handscraped guide ways provides stable hydraulic movement and the best dressing effects. Various types of form dressing can be achieved with optional templates.

- NC model: optional auto. grinding wheel dressing device enables count dressing, time dressing, or auto dressing and compensation

- CNC model: with two axes servo control and the automatic compensation system can precisely dress forms with complicated shapes.

- Various workrest design: e-tech developed various kinds of workrest based on different diameter of workpieces, which are easy for operating adjustment.

2

The regulating wheel utilizes a servo motor which provides infinitely variable speeds. The speed can be set digitally to reach constant surface speeds even when the diameter of the regulating wheel changes. Consequently, better surface finishes and roundness of the workpiece can be achieved. A beltdriven transmission system is also adopted for the regulating wheel for less vibration and noise compare to traditional chain-driven system.

3

Both grinding & regulating wheel spindles are made of Ni-Cr-Mo alloy steel, which is normalized, carbonized, hardened and grounded.

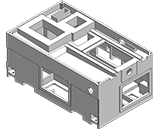

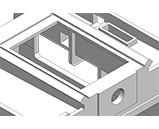

4

The machine base is made of Meehanite castings designed to reduce vibration. The machine base provides stable support to the grinding wheel and regulating wheel assemblies to ensure a rigid machine foundation and better accuracy.

5

A double inverted “V” slideway with optimum spacing for the regulating wheel assembly provides smooth movement and stable grinding operation.

6

Automatic infeed models (NC) are equipped with a PLC touch screen control with easy learning conversational software.

An infeed grinding cycle can be completed by simply choosing the grinding cycle mode (single or automatic), inputting grinding data and then pressing cycle start.

Applications

Explore by industry to discover which types of workpieces are supported by e-tech’s grinding solutions.

Specification

| ECG-NC1206 | ECG-NC1808/1810/1812 | ECG-NC2008/2010/2012 | |

| Work Diameter (W / Standard Workrest) |

∅1-30 mm | ∅1-60 mm | ∅1-60 mm |

| Work Diameter (W / Special Workrest) | ∅30-50 mm | ∅60-100 mm | ∅60-120 mm |

| Wheel Size {OD x Width x ID) 08 Type | ∅305x150x∅120 mm | ∅455x205x∅228.6 mm | ∅510x205x∅304.8 mm |

| Wheel size {OD x Width x ID) 10 Type | N/A mm | ∅455x255x∅228.6 mm | ∅510x255x∅304.8 mm |

| Wheel size {OD x Width x ID) 12 Type | N/A mm | ∅455x305x∅228.6 mm | ∅510x305x∅304.8 mm |

Learn More About Our Product

For more detailed information, please download our catalog. The catalog includes standard accessories, optional accessories, and a comprehensive specification guide to help you better understand our product’s features!