R&D Design

Innovation That Moves the Industry Forward

Innovation drives everything we do. At our R&D center, we are constantly improving and evolving our machines through in-house development and patented technologies. Each advancement is the result of hands-on experience and customer-driven design — boosting not only machine performance, but also delivering real value where it matters most: on the production floor. These technical breakthroughs continue to strengthen e-tech’s position as a trusted partner in high-precision grinding solutions.

Global R&D Vision

Our R&D philosophy is closely aligned with leading advancements in Europe, the U.S., and Japan — always driven by customer needs and market trends. We stay ahead by closely monitoring shifts in industry direction and future development. At e-tech, innovation isn’t reactive — it’s proactive. We focus on developing products with the potential to drive future demand, strengthen market competitiveness, and support long-term business growth. This forward-thinking approach fuels our momentum and ensures we continue to thrive in a rapidly evolving manufacturing landscape.

Quality Management

Our Quality Promise

Quality is the foundation of everything we do—and the most fundamental promise we make to our customers. At e-tech, we are deeply committed to continuous improvement, applying rigorous analysis and testing to every machine we build. This not only sharpens our precision but also strengthens the trust our customers place in our brand.

Certified Excellence:

- ISO 9001 Certified

- TS Certification

- CE Mark

Each certification reflects our dedication to maintaining the highest standards in quality and performance.

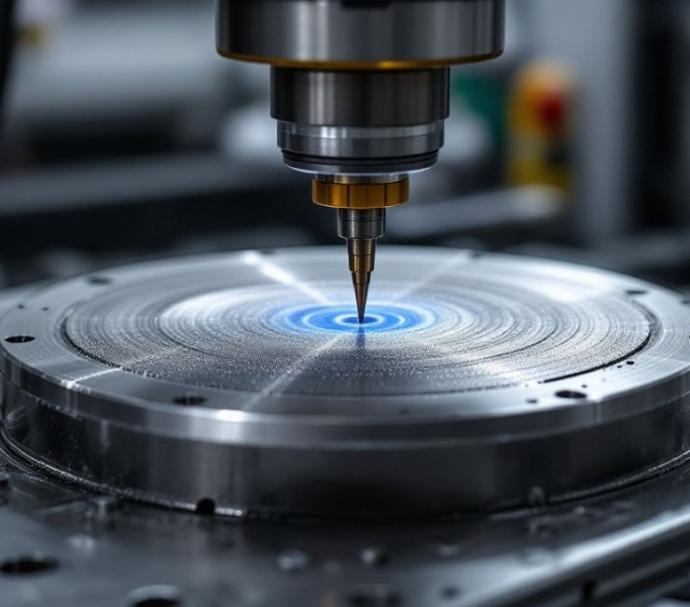

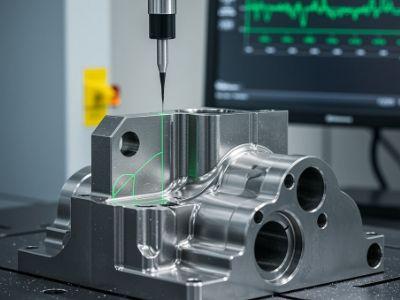

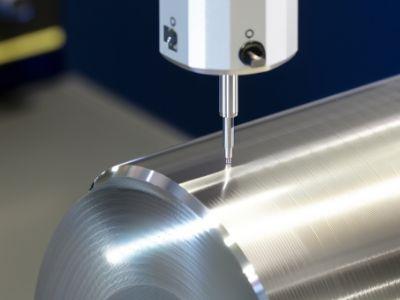

Ensuring Accuracy & Reliability

To ensure customers can use e-tech products with confidence, we operate under the principle of "Quality First, Customer Satisfaction, and Continuous Improvement."

From incoming inspection to manufacturing and final testing, we invest in both advanced measurement tools and skilled QA professionals to guarantee accuracy and reliability across every unit.

Our comprehensive measurement equipment includes:

Hardness Tester

Roundness Tester

Contour Measuring Instrument

Surface Roughness Tester

3D Coordinate Measuring Machine

We also provide test grinding services. Customers may submit samples for trial machining, after which our QA team delivers professional inspection reports and personalized grinding recommendations—helping customers identify the best-fit solution with optimal efficiency.

Total Quality Management

At e-tech, Total Quality Management (TQM) is not just a process — it’s a mindset.

Through standardized procedures, structured training, and continuous improvement via the PDCA cycle, we build company-wide quality ownership and operational excellence.

Standardized Workflows

We convert valuable experience into structured procedures and training for consistent execution.

Established SOPs Across All Production Lines

Every process follows well-defined SOPs to maintain stable, repeatable product quality.procedures and training for consistent execution.

Continuous Employee Training

We cultivate a culture of quality through ongoing staff education and skill development.

PDCA Cycle Application

(Plan → Do → Check → Act)

Our improvement strategy revolves around continuous refinement using the PDCA methodology.

Company-wide Quality Ownership

Quality isn’t just a department’s duty — it’s an organization-wide commitment.

Mindset-Driven TQM Philosophy

Beyond systems, TQM at e-tech is a mindset embedded in every team member’s work ethic.

Testing & Inspection Procedures

Spindle Run-in Test

In-Process Inspection

Pre-Shipment Trial Grinding

Customer Sample Grinding & Measurement

Final Machine Inspection

Advanced Process Analysis