Standard Grinding Cycles And Multi-Steps Graphic

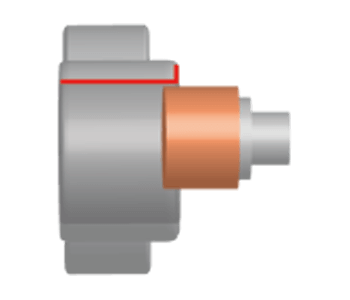

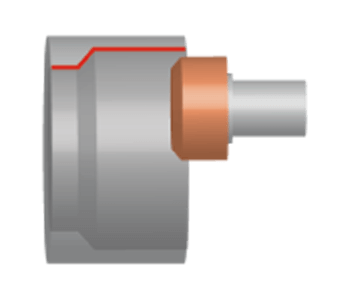

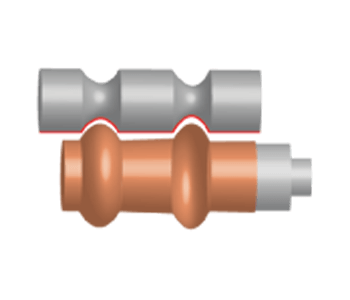

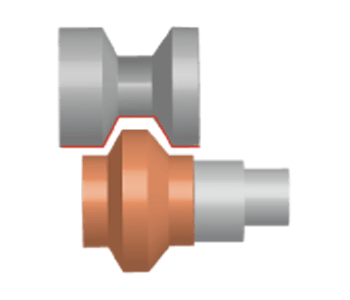

Inner through hole

Inner through hole

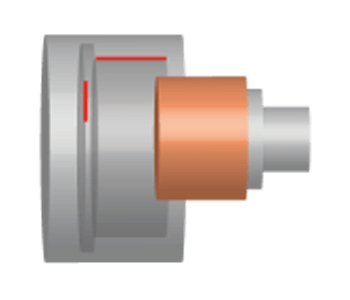

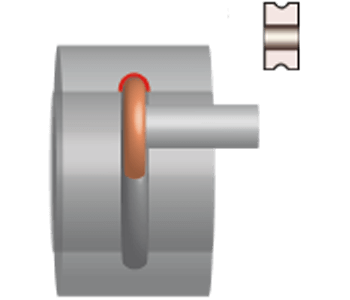

2 Step straight hole

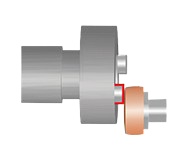

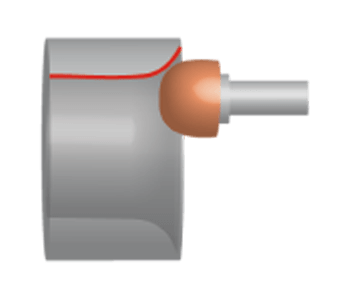

Inner through hole + outer end-face (gear tip)

Inner blind hole + Inner end-face

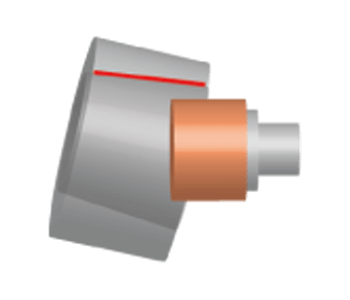

Inner taper

Outer diameter + End surface (EGM-350LF)

Inner blind hole + ID chamer

Inner radius groovin

Inner through hole + Inner radius

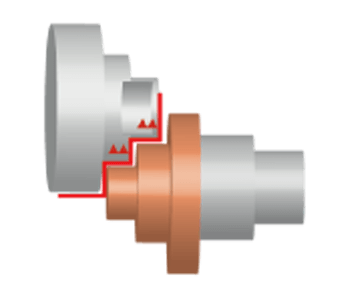

Multi-step grinding

Profile grinding

Inner diameter + End surface

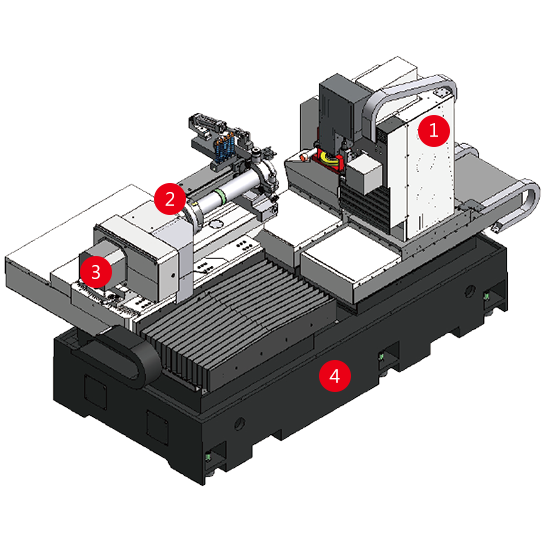

Machine Design Feature

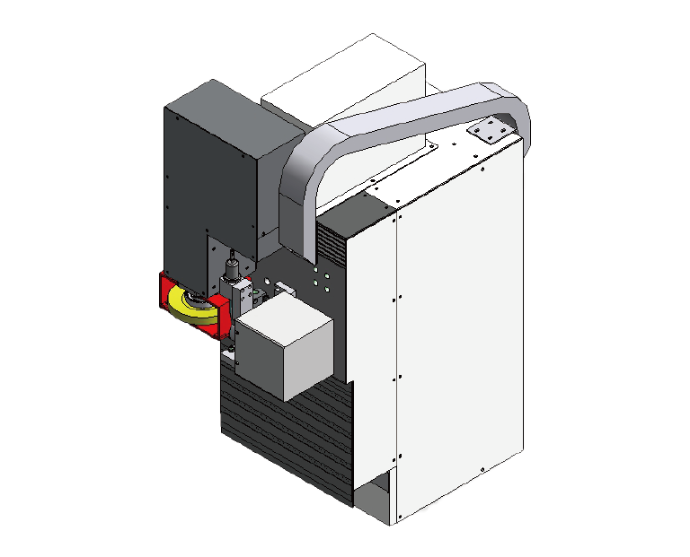

1

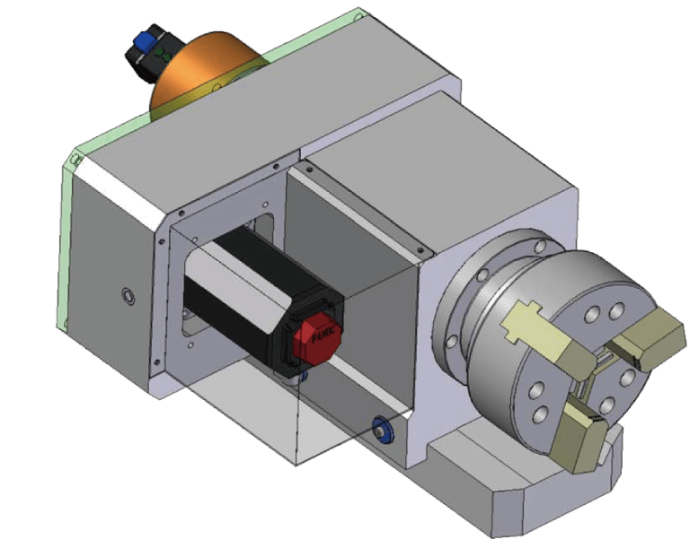

We add in a vertical slide mechanical structure. You can chose general grinding wheel or diamond grinding wheel grinding the end face of the spindle and the two surface planes of the locating key with touch probe to achieve automatic positioning and automatic grinding.

2

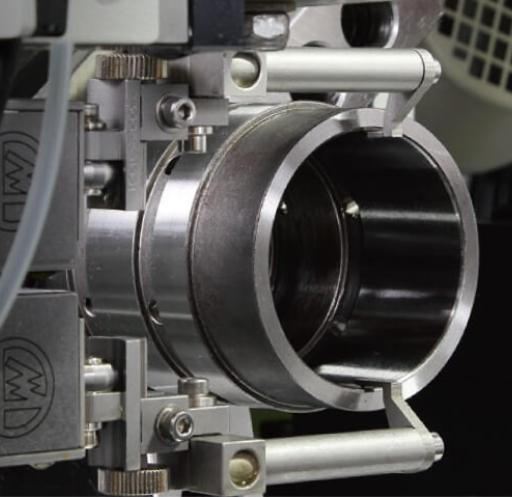

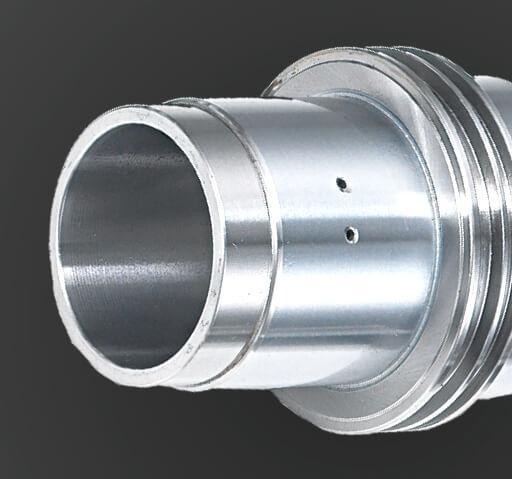

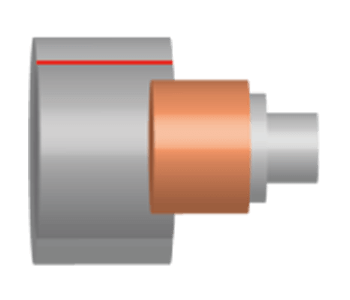

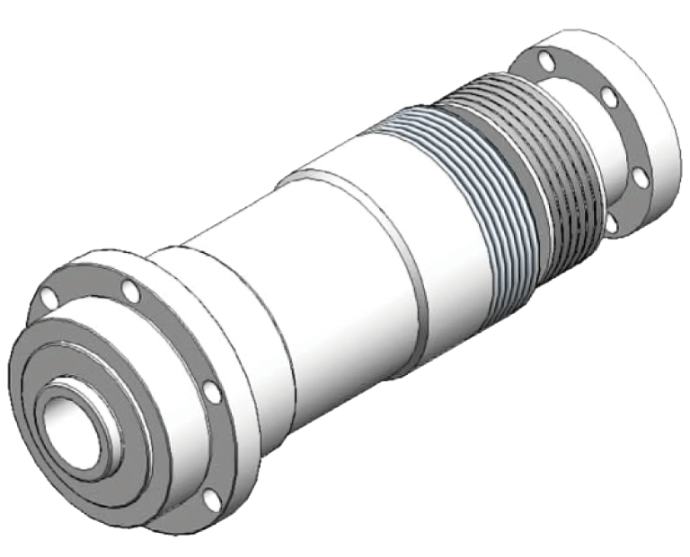

Complete one piece cartridge spindle can avoid the eccentricity of spindle housing and reduces the heat increase for spindle life.

3

Spindle driven by servo motor offers optimum speed and torque performance.

4

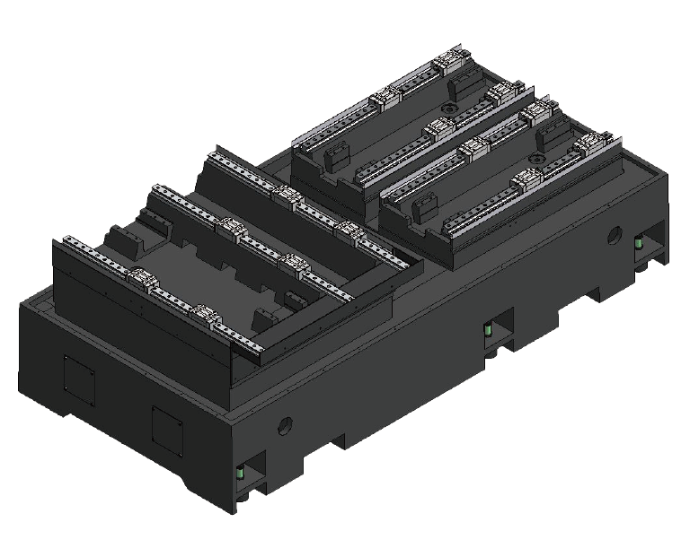

Low-gravity base structure, with slant bed design for better coolant draining and grinding swarf removal.

Applications

Explore by industry to discover which types of workpieces are supported by e-tech’s grinding solutions.

Specification

| EGM-350LF | |

| Max. grinding ID | ∅300 mm |

| Max. grinding OD | ∅330 mm |

| Swing over workhead | ∅340 mm |

| Max. grinding depth | 260 mm |

| Max. weight of workpiece | 300(w/steady rest) kg |

| Max. length of workpiece | 750 mm |

Learn More About Our Product

For more detailed information, please download our catalog. The catalog includes standard accessories, optional accessories, and a comprehensive specification guide to help you better understand our product’s features!