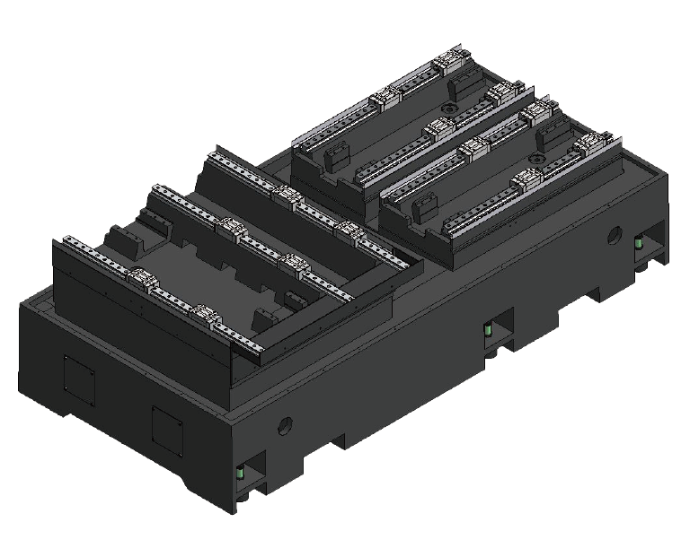

Standard Grinding Cycles And Multi-Steps Graphic

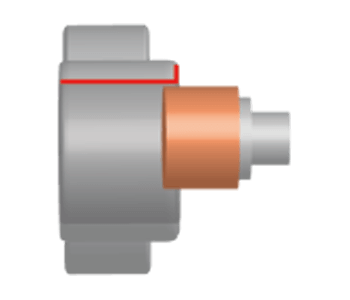

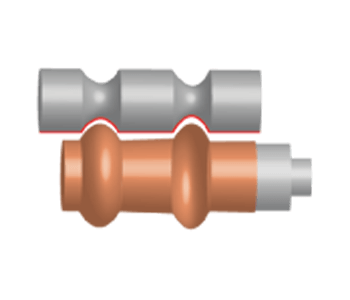

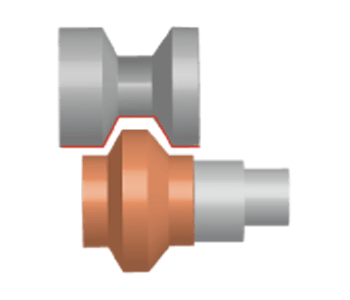

Inner through hole

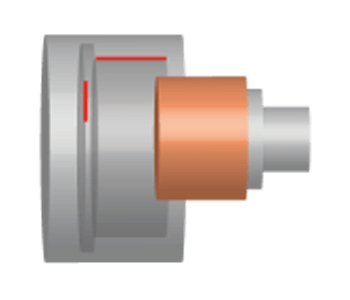

2 Step straight hole

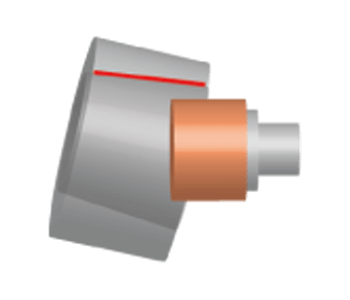

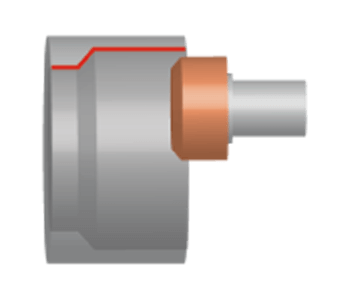

Inner through hole + outer end-face (gear tip)

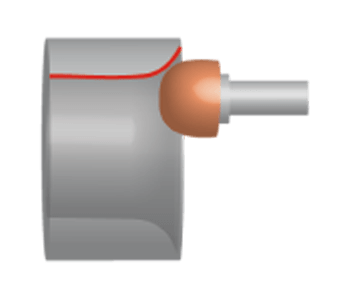

Inner blind hole + Inner end-face

Inner taper

Multi-process in one-stop (EGM-350T)

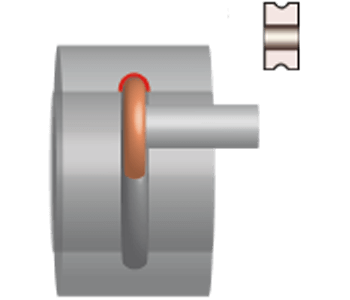

Inner blind hole + ID chamer

Inner radius groovin

Inner through hole + Inner radius

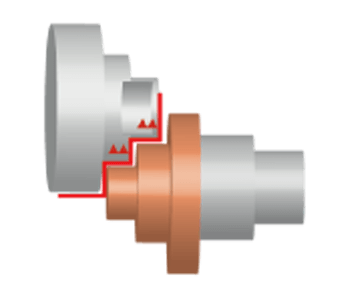

Multi-step grinding

Profile grinding

Inner diameter + End surface

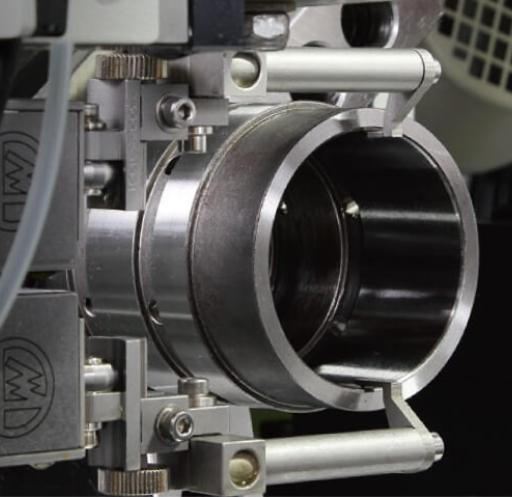

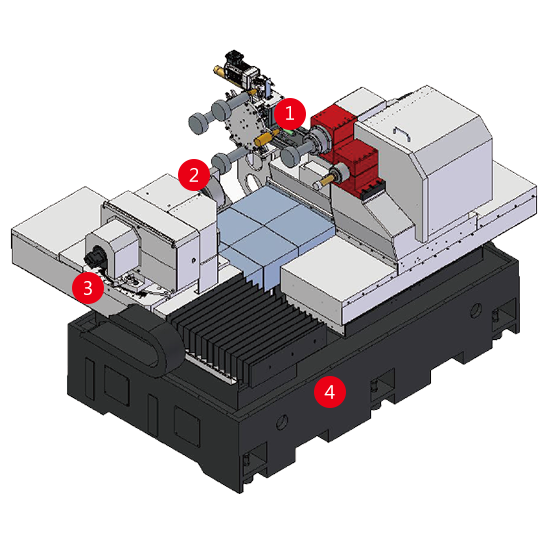

Machine Design Feature

1

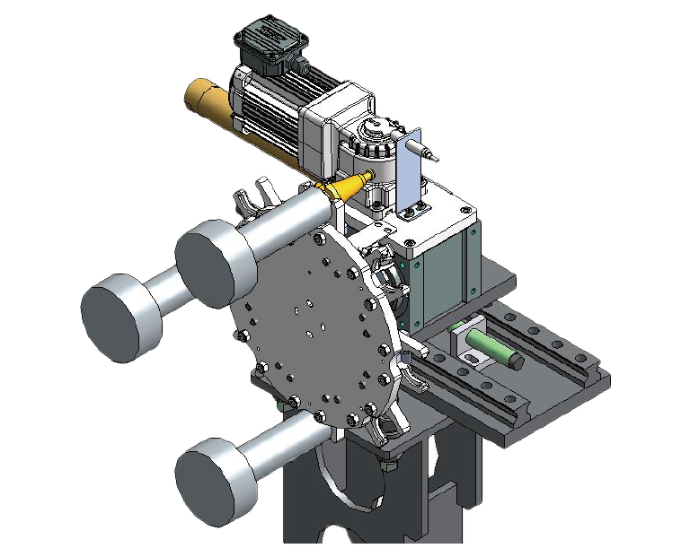

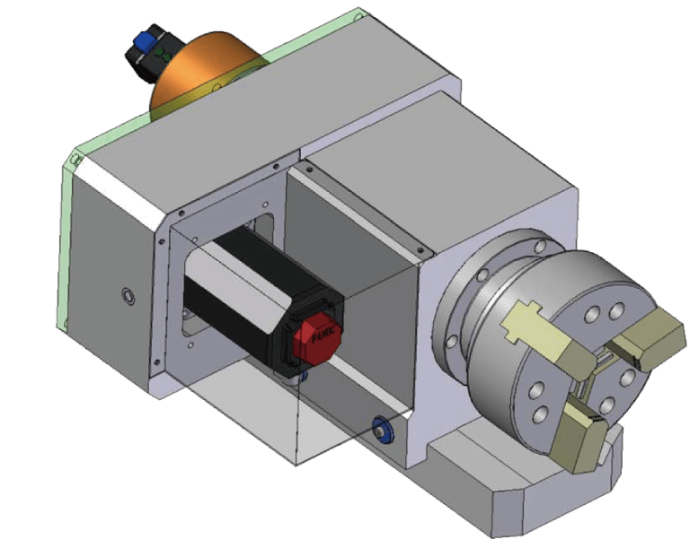

The spindle we choose is BBT30 built-in type ATC spindle with 7.5kw and 30,000RPM. The tool magazine is driven by precision hydraulic slide, and can be equipped up to 8 tools in max., according to the size of the wheel.

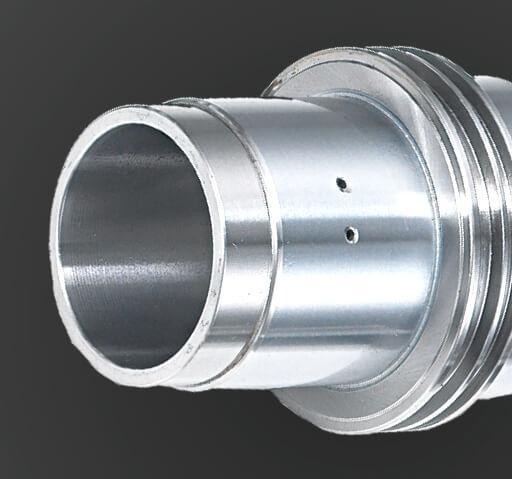

2

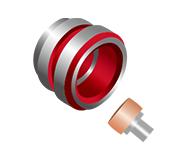

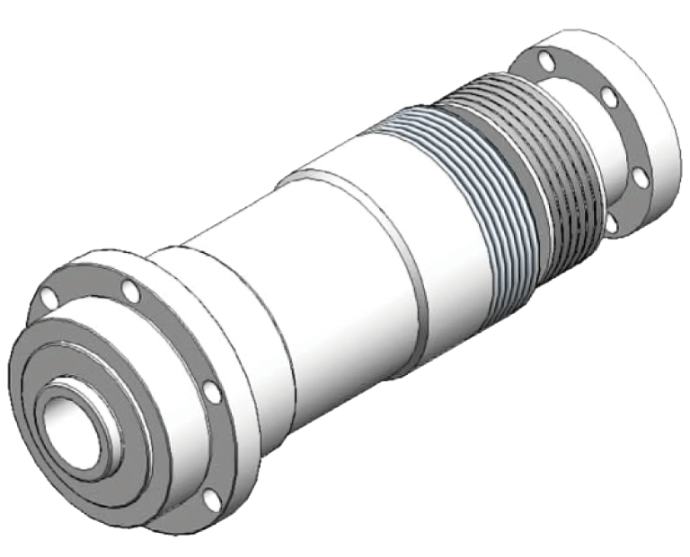

Complete one piece cartridge spindle can avoid the eccentricity of spindle housing and reduces the heat increase for spindle life.

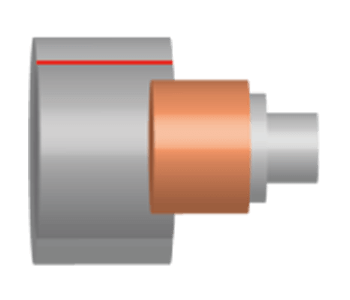

3

Spindle driven by servo motor offers optimum speed and torque performance.

4

Low-gravity base structure, with slant bed design for better coolant draining and grinding swarf removal.

Applications

Explore by industry to discover which types of workpieces are supported by e-tech’s grinding solutions.

Specification

| EGM-350TCNC |

|

| Max. Grinding ID | ∅300 mm |

| Max. Grinding OD | ∅400 mm |

| Swing Over Workhead | ∅500 mm |

| Max. Grinding Depth | 260 mm |

| Max. Weight of Workpiece | 50 kg |

| Max. Length of Workpiece | 300 mm |

| Max. Spindle Speed | 30000(Build-in-spindle) mm |

| Tool Holder | BBT30 |

| Tool Magazine Capacity | 8 Qty. |

Learn More About Our Product

For more detailed information, please download our catalog. The catalog includes standard accessories, optional accessories, and a comprehensive specification guide to help you better understand our product’s features!