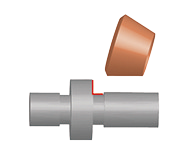

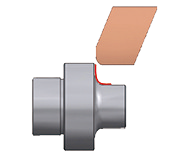

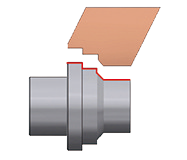

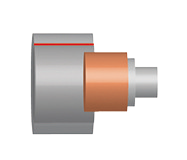

Grinding Cycle

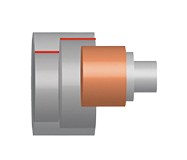

Plunge grinding

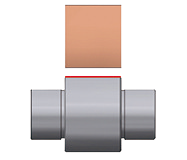

Plunge grinding

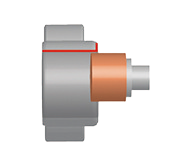

OD+Radius+Face

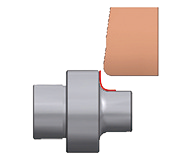

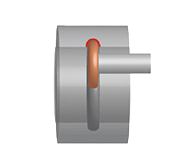

Profile grinding

Profile grinding

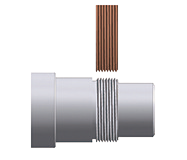

Thread grinding

Outer diameter+End Surface

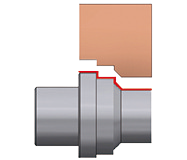

OD+Radius+Face

Angular profile grinding

Inner through hole

2 steps straight hole

2 steps straight hole

Inner throgh hole+outer end face(gear trip)

Inner radius grooving

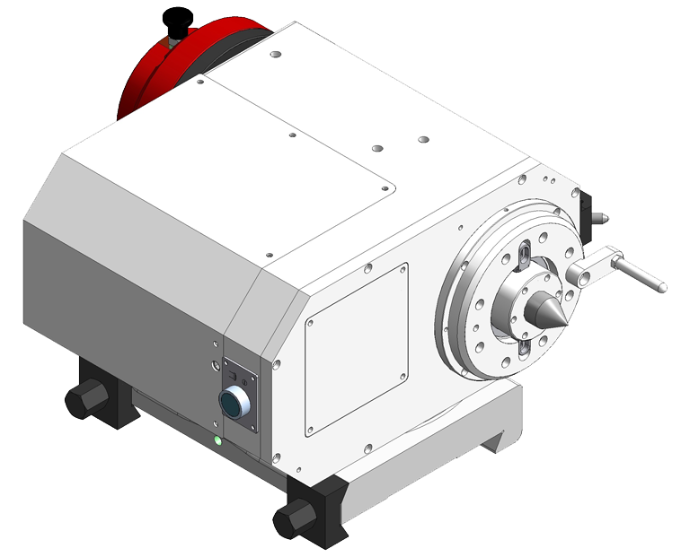

Machine Design Feature

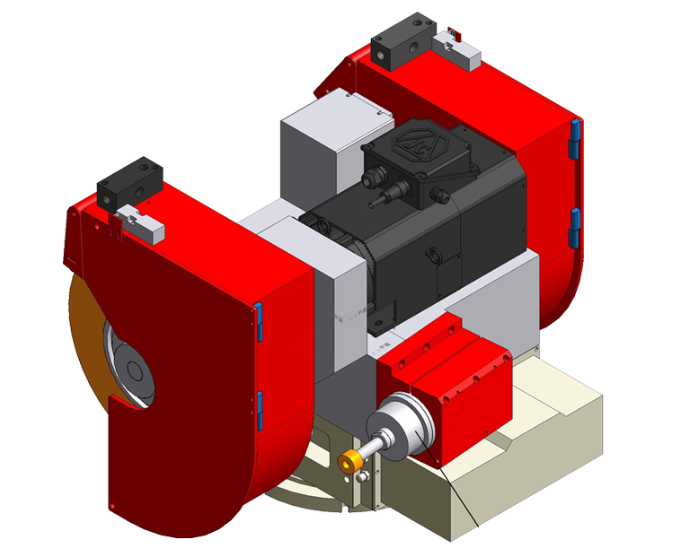

1

NN bearing designed work spindle offers heavy duty load capacity, optimal rotation accuracy, and high rigidity. The servo motor drive offers steady speed and torque during the grinding operation. A positive air purge system keeps grinding swarf and coolant out of the work head, thus it prolongs its life.

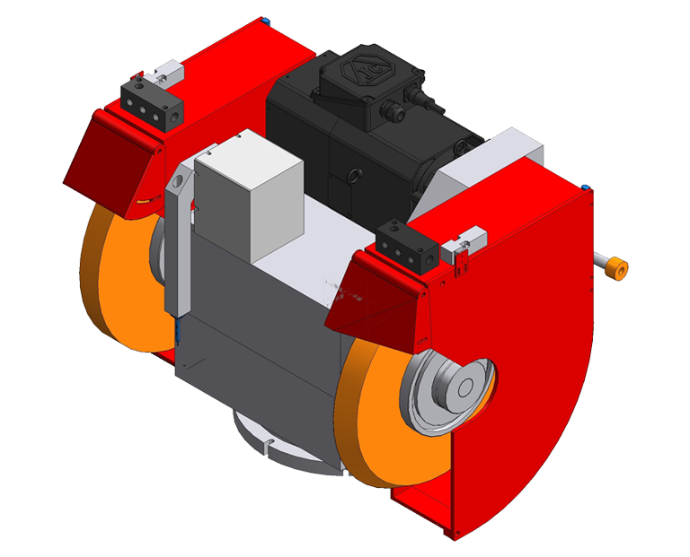

2

T1 and T1 share a spindle. NN bearing designed work spindle ensures rigidity and accuracy while grinding, and provides a bigger output power to increase grinding efficiency. (Standard line speed:45 m/sec).

3

ID grinding spindle of T3 axis is designed with built-in spindle. It not only reduces the space, but provides steady torque and rigidity. (Opt.)

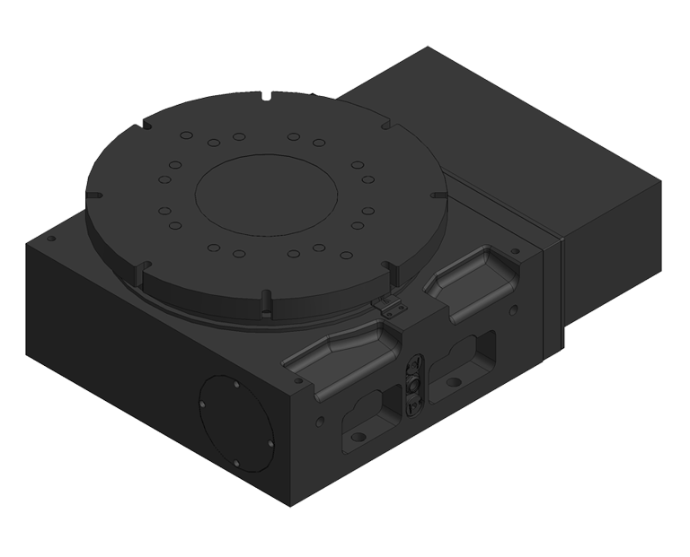

4

Positioning by two-piece tooth type clutch gear and hydraulic brake. It is high positioning accuracy, able to hold heavy-duty working, and good water-proof.

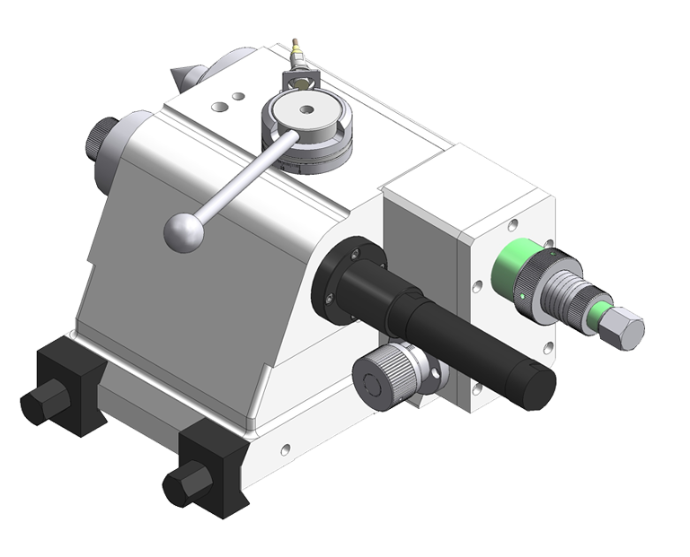

5

A coolant nozzle is installed on the top of the tailstock for cooling the center tip. An air floating devise allows for smoother movement and protection of the table. It is capable of slightly adjustment and no need to reset dressing zero. -An optional tailstock quill travel of 50 and 75mm helps to load/unload the workpiece with ease. The quill is oil-bathed to ensure smooth movement. -An optional tailstock taper adjustment feature allows the operator to easily adjust for taper error.

6

The box structure design, the thickness of the frame and rail ribs of this table are 25mm, and the remaining 20mm, can show the best rigidity and stability, and ensure the grinding accuracy and quality. The clean and cool water pipe of this machine is arranged inside the machine, and there are three water outlet holes on the table, which is convenient and beautiful.

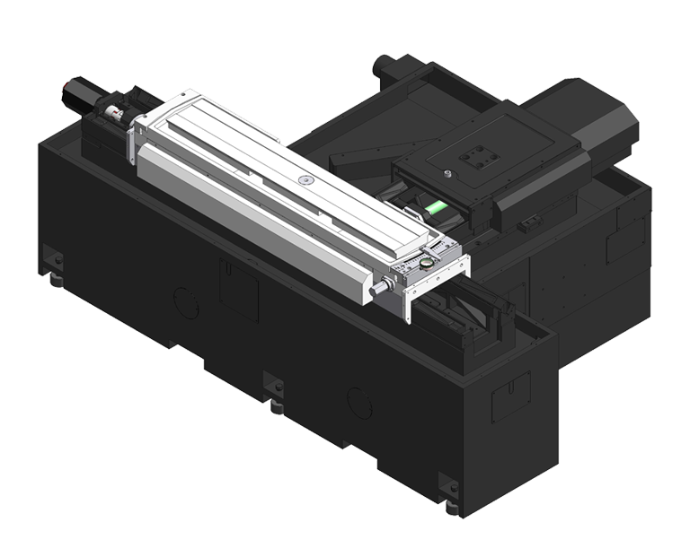

7

The hand scraped Double V guideways provide maximum support to the wheel head for greater stability and grinding capacity. This design insures superior accuracy over the life of the machine.

Specification

| EGP-3260BCNC | EGP-32100BCNC | EGP-32150BCNC | EGP-3860BCNC | EGP-38100BCNC | EGP-38150BCNC | EGP-5060BCNC | EGP-50100BCNC | EGP-50150BCNC | |

| Swing Over Table | Ø320 mm | Ø320 mm | Ø320 mm | Ø380 mm | Ø380 mm | Ø380 mm | Ø500 mm | Ø500 mm | Ø500 mm |

| Distance Between Centers | 600 mm | 1000 mm | 1500 mm | 600 mm | 1000 mm | 1500 mm | 600 mm | 1000 mm | 1500 mm |

| Max. Grinding Diameter | Ø300 mm | Ø300 mm | Ø300 mm | Ø360 mm | Ø360 mm | Ø360 mm | Ø480 mm | Ø480 mm | Ø480 mm |

| Max. Load Held Between Center | 150 kg | 150 kg | 150 kg | 150 kg | 150 kg | 150 kg | 150 kg | 150 kg | 150 kg |

| Center Distance Between Spindle and Slide Table | 162 mm | 162 mm | 162 mm | 192 mm | 192 mm | 192 mm | 255 mm | 255 mm | 255 mm |

Learn More About Our Product

For more detailed information, please download our catalog. The catalog includes standard accessories, optional accessories, and a comprehensive specification guide to help you better understand our product’s features!